SobieskiSavedEurope

Gold Member

- Thread starter

- Banned

- #441

Polish-built robot flies to Mars on NASA mission

05.05.2018 08:30

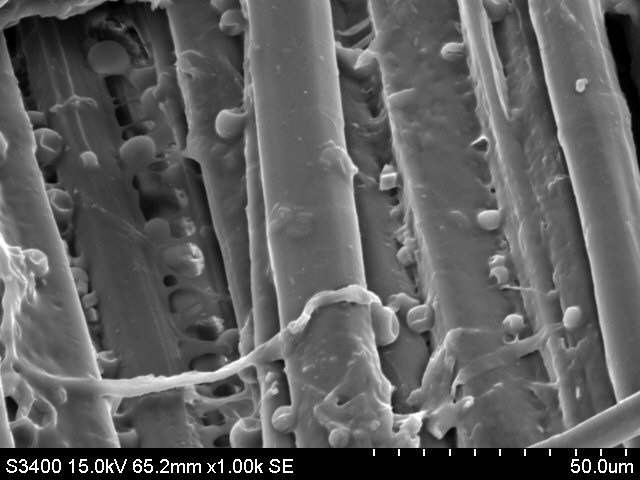

A hi-tech robotic device designed and built by a Polish company was on Saturday scheduled to be launched to Mars on board a NASA spacecraft.

Image: ColiN00B/pixabay.com/CC0 Creative Commons

Image: ColiN00B/pixabay.com/CC0 Creative Commons

The device, described as a self-hammering mechanism, is a component of a heat probe that will examine the thermal properties of the Red Planet.

The main goal of the US space agency’s InSight mission — launching on Saturday from Vandenberg Air Force Base in central California — is to give scientists a better understanding of the structure and geological activity of Mars.

The InSight lander is scheduled to touch down on the Red Planet on November 26 after a journey of 485 million kilometres. It is expected to remain active there for two years.

The self-hammering instrument has been developed by innovative Warsaw company Astronika, which was founded in 2013 by a group of Polish engineers specialising in precision mechanics and space technology.

(gs/pk)

Source: PAP, astronika.pl

tags: Mars, NASA

Polish-built robot flies to Mars on NASA mission

05.05.2018 08:30

A hi-tech robotic device designed and built by a Polish company was on Saturday scheduled to be launched to Mars on board a NASA spacecraft.

The device, described as a self-hammering mechanism, is a component of a heat probe that will examine the thermal properties of the Red Planet.

The main goal of the US space agency’s InSight mission — launching on Saturday from Vandenberg Air Force Base in central California — is to give scientists a better understanding of the structure and geological activity of Mars.

The InSight lander is scheduled to touch down on the Red Planet on November 26 after a journey of 485 million kilometres. It is expected to remain active there for two years.

The self-hammering instrument has been developed by innovative Warsaw company Astronika, which was founded in 2013 by a group of Polish engineers specialising in precision mechanics and space technology.

(gs/pk)

Source: PAP, astronika.pl

tags: Mars, NASA

Polish-built robot flies to Mars on NASA mission