Missourian

Diamond Member

Trigger warning... Nothing you see in this thread will be up to code.

Mrs Mo calls me on the road yesterday... says I need to call the water company... the bill says we used 31,000 of water last month. The water company says am I sure I don't have a leak?

Long story short... some previous owner decided burying a 3/4" galvanized pipe in the crawlspace was a brilliant idea... then to add insult to injury... they plopped a huge rock on to of it to keep it from cavitating. That is what was leaking.

Most of the house was PVC and CPVC, but this was some of the oldest galvanized pipe.

Usually I just take it out and replace it with pvc or pex...but this one runs inside the wall and that pipe still looks good...so I figure... no problem... I'll replace as much as I can... then I'll sharkbite the galvanized to pex and Bob's your Uncle we'll be gtg.

Nope.

First... even though pvc and galvanized pipe are virtually the same diameter... everything I've read says sharkbites are not recommended for galvanized pipe.

Also... even if some redneck wanted to see for himself if it would work or not... the local hardware store didn't stock them.

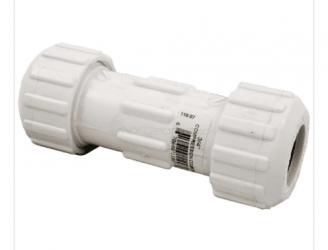

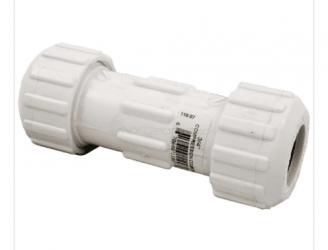

Plan B was a dual compression fitting coupler like this one.

They didn't have that either.

Plan C was one of those black rubber connectors with hose clamps. The smallest size available was 1.25".

Soooo on to plan D... scour the hardware store looking for something that would work.

What I came up with was a braided vinyl hose rated to 175 psi (double the maximum house water pressure). It was 1" ID... which is the OD of the 3/4 inch galvanized and the 3/4 pvc, some 1.25 inch pvc whose inside diameter matched the outside diameter of the braided tubing, and a couple of hose clamps plus various connectors.

The galvanized pipe stub is a piece I cut off the old pipe and took to the hardware store with me.

So far, so good... not a drip nor drop of leaking.

Needless to say... this is not a proper or permanent repair... it's just to get though until I can replace the pipe in the wall.

That pipe runs the cold water to the full bathroom upstairs AND the only shower.

Mrs Mo calls me on the road yesterday... says I need to call the water company... the bill says we used 31,000 of water last month. The water company says am I sure I don't have a leak?

Long story short... some previous owner decided burying a 3/4" galvanized pipe in the crawlspace was a brilliant idea... then to add insult to injury... they plopped a huge rock on to of it to keep it from cavitating. That is what was leaking.

Most of the house was PVC and CPVC, but this was some of the oldest galvanized pipe.

Usually I just take it out and replace it with pvc or pex...but this one runs inside the wall and that pipe still looks good...so I figure... no problem... I'll replace as much as I can... then I'll sharkbite the galvanized to pex and Bob's your Uncle we'll be gtg.

Nope.

First... even though pvc and galvanized pipe are virtually the same diameter... everything I've read says sharkbites are not recommended for galvanized pipe.

Also... even if some redneck wanted to see for himself if it would work or not... the local hardware store didn't stock them.

Plan B was a dual compression fitting coupler like this one.

They didn't have that either.

Plan C was one of those black rubber connectors with hose clamps. The smallest size available was 1.25".

Soooo on to plan D... scour the hardware store looking for something that would work.

What I came up with was a braided vinyl hose rated to 175 psi (double the maximum house water pressure). It was 1" ID... which is the OD of the 3/4 inch galvanized and the 3/4 pvc, some 1.25 inch pvc whose inside diameter matched the outside diameter of the braided tubing, and a couple of hose clamps plus various connectors.

The galvanized pipe stub is a piece I cut off the old pipe and took to the hardware store with me.

So far, so good... not a drip nor drop of leaking.

Needless to say... this is not a proper or permanent repair... it's just to get though until I can replace the pipe in the wall.

That pipe runs the cold water to the full bathroom upstairs AND the only shower.

Last edited: