Thank you, but I did not understand what you mean?

Here

- the lower frame of the frame structure

- fastenings and connections

- "slanting strips" are not installed

- waterproofing

View attachment 215504

Why did you knotch the inside of the lag bolts...........I understand knotching the outside to give the runner extra support, but why knotch the inner side...............

Yeah there's a lot going on there I don't really get...

You mean like there is no solid foundation?

Concrete blocks on gravel is no way to build anything

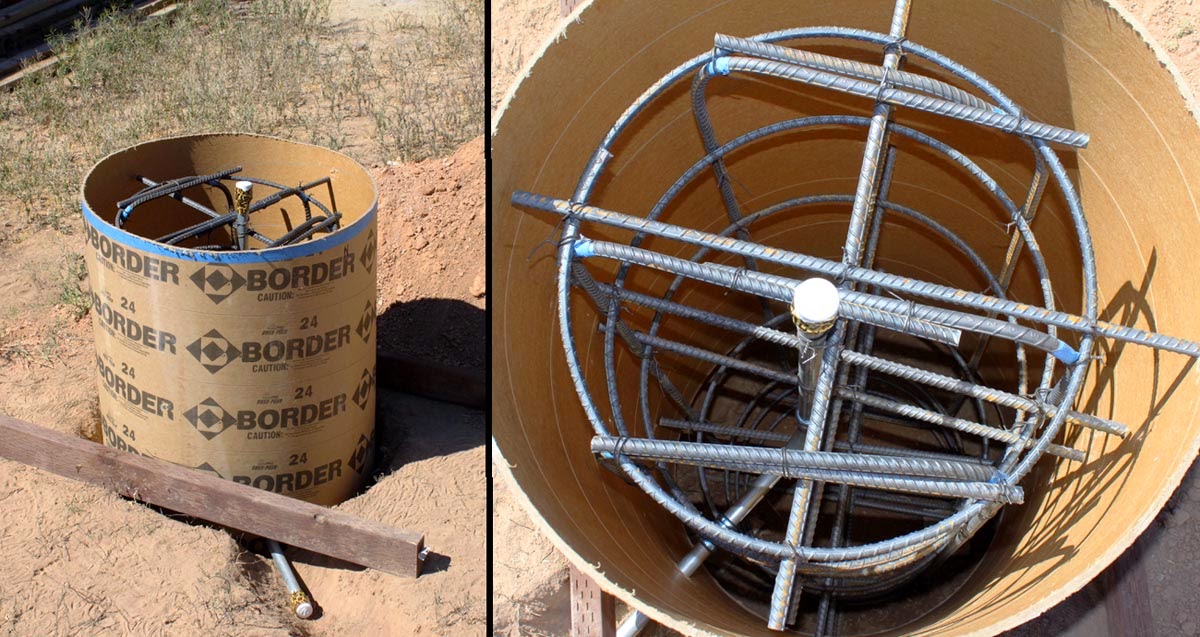

He did concrete forms into the ground..........to the frost line......which we can't see........then anchored some 2 x's into it....and did a square frame on the concrete post on the edges of the concrete pour..........

You can put those in during the concrete pour and put the 6 x 6 directly on the center of the concrete pour.

A nightmare

. If you do this, the wooden rack will rot.

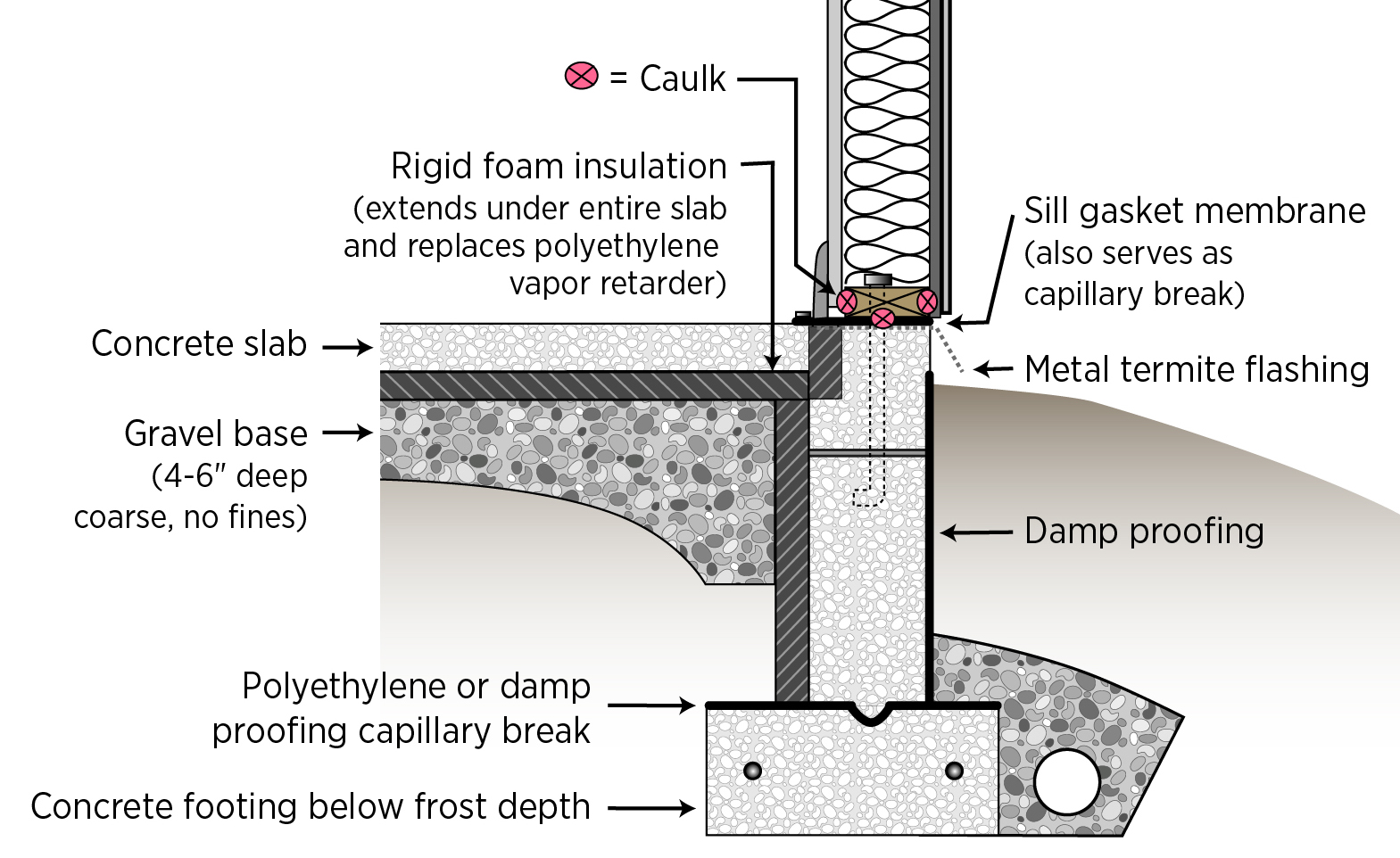

There is no waterproofing, no ventilation ..

As you know, concrete has the property of "pulling water from the ground," so any wooden structure that is put on concrete must be waterproofed. !!!!

This is protection from groundwater In addition, one should never allow water after rain to accumulate under a wooden structure This is protection from atmospheric water Finally.. Any wooden structure should be located not lower than the height of the snow cover. Approximately 50 cm. This rule is leveled, if you lay rubble .

.. GOST (Government standard) of the USSR "storage of softwood" My photo shows how to do it.