We're simply a far better country for nasa and space exploration. There's really no debate and one day if we have any intelligence at all we'll go get the resources....

here is some more innovation!

Highway safety

Safety grooving, the cutting of grooves in concrete to increase traction and prevent injury, was first developed to reduce aircraft accidents on wet runways. Represented by the International Grooving and Grinding Association, the industry expanded into highway and pedestrian applications. Safety grooving originated at Langley Research Center, which assisted in testing the grooving at airports and on highways. Skidding was reduced, stopping distance decreased, and a vehicle’s cornering ability on curves was increased. The process has been extended to animal holding pens, parking lots, and other potentially slippery surfaces.

[13]

Improved radial tires

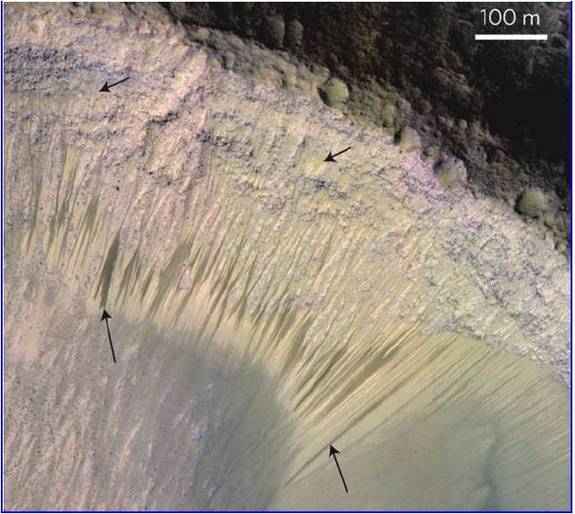

Goodyear Tire and Rubber Company developed a fibrous material, five times stronger than steel, for NASA to use in parachute shrouds to soft-land the

Viking Lander spacecraft on the Martian surface. Recognizing the durability of the material, Goodyear expanded the technology and went on to produce a new radial tire with a tread life expected to be 10,000 miles (16,000 km) greater than conventional radials.

[14]

Chemical detection

NASA contracted with Intelligent Optical Systems (IOS) to develop moisture- and pH-sensitive sensors to warn of corrosive conditions in aircraft before damage occurs. This sensor changes color in response to contact with its target. After completing the work with NASA, IOS was tasked by the U.S. Department of Defense to further develop the sensors for detecting chemical warfare agents and potential threats, such as toxic industrial compounds and nerve agents. IOS has sold the chemically sensitive fiber optic cables to major automotive and aerospace companies, who are finding a variety of uses for the devices such as aiding experimentation with nontraditional power sources, and as an economical "alarm system" for detecting chemical release in large facilities.

[12]

Public safety

Video enhancing and analysis systems

Intergraph Government Solutions developed its Video Analyst System (VAS) by building on Video Image Stabilization and Registration (VISAR) technology created by NASA to help FBI agents analyze video footage. Originally used for enhancing video images from nighttime videotapes made with hand-held camcorders, VAS is a tool for video enhancement and analysis offering support of full-resolution digital video, stabilization, frame-by-frame analysis, conversion of analog video to digital storage formats, and increased visibility of filmed subjects without altering underlying footage. Aside from law enforcement and security applications, VAS has also been adapted to serve the military for reconnaissance, weapons deployment, damage assessment, training, and mission debriefing.

[15]

Fire-resistant reinforcement

Built and designed by Avco Corporation, the Apollo heat shield was coated with a material whose purpose was to burn and thus dissipate energy during reentry while charring, to form a protective coating to block heat penetration. NASA subsequently funded Avco’s development of other applications of the heat shield, such as fire-retardant paints and foams for aircraft, which led to intumescent epoxy material, which expands in volume when exposed to heat or flames, acting as an insulating barrier and dissipating heat through burn-off. Further innovations include steel coatings devised to make high-rise buildings and public structures safer by swelling to provide a tough and stable insulating layer over the steel for up to 4 hours of fire protection, ultimately to slow building collapse and provide more time for escape.

[16]

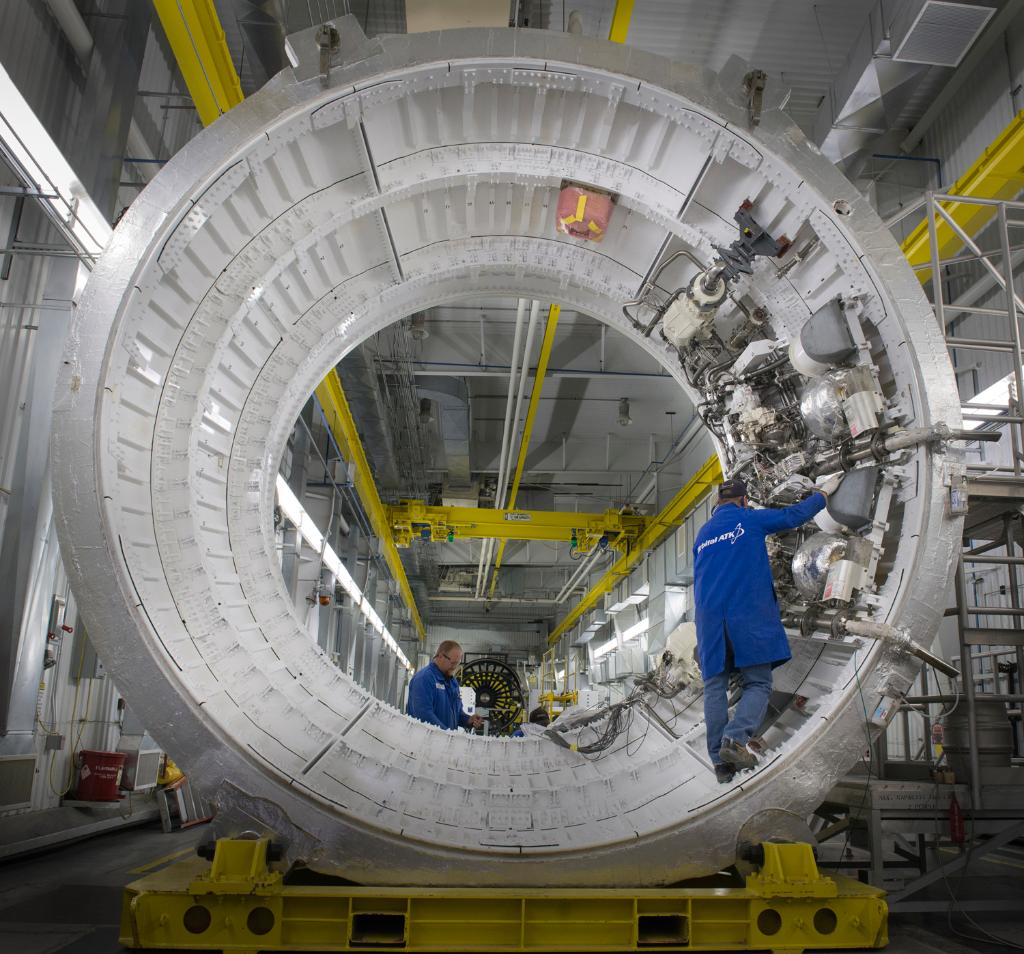

Firefighting equipment

Firefighting equipment in the United States is based on lightweight materials developed for the U.S. Space Program. NASA and the National Bureau of Standards created a lightweight breathing system including face mask, frame, harness, and air bottle, using an aluminum composite material developed by NASA for use on rocket casings. The broadest fire-related technology transfer is the breathing apparatus for protection from smoke inhalation injury. Additionally, NASA’s inductorless electronic circuit technology led to lower-cost, more rugged, short-range two-way radio now used by firefighters. NASA also helped develop a specialized mask weighing less than 3 ounces (85 g) to protect the physically impaired from injuries to the face and head, as well as flexible, heat-resistant materials—developed to protect the space shuttle on reentry—which are being used both by the military and commercially in suits for municipal and aircraft-rescue firefighters.

[17][18][19][20]

Consumer, home, and recreation

Temper foam

Initially referred to as "slow spring back foam", temper foam matches pressure against it and slowly returns to its original form once the pressure is removed.

As the result of a program designed to develop a padding concept to improve crash protection for airplane passengers, Ames Research Center developed what is now called memory foam. Memory foam, or "Temper Foam", has been incorporated into mattresses, pillows, military and civilian aircraft, automobiles and motorcycles, sports safety equipment, amusement park rides and arenas, horseback saddles, archery targets, furniture, and human and animal prostheses. Its high-energy absorption and soft characteristics offer protection and comfort. Temper Foam was inducted into the

Space Foundation Space Technology Hall of Fame in 1998.

[9][10]:46–49

[14][18][21][22][23]

Enriched baby food

Commercially available infant formulas now contain a nutritional enrichment ingredient that traces its existence to NASA-sponsored research on bread mold as a recycling agent for long-duration space travel. The substance, formulated into the products life’sDHA and life’sARA and based on microalgae, can be found in over 90% of the infant formulas sold in the United States, and are added to infant formulas in over 65 other countries. Martek Biosciences Corporation's founders and principal scientists acquired their expertise in this area while working on the NASA program. The microalgae food supplement was inducted into the

Space Foundation Space Technology Hall of Fame in 2009.

[24]

Portable cordless vacuums

For the Apollo space mission, NASA required a portable, self-contained drill capable of extracting core samples from below the lunar surface.

Black & Decker was tasked with the job, and developed a computer program to optimize the design of the drill’s motor and ensure minimal power consumption. That computer program led to the development of a cordless miniature vacuum cleaner called the Dustbuster.

[18]

Freeze drying

In planning for the long-duration Apollo missions, NASA conducted extensive research into space food. One of the techniques developed in 1938 by Nestlé was

freeze drying. In the United States, Action Products later commercialized this technique for other foods, concentrating on snack food resulting in products like

Space ice cream. The foods are cooked, quickly frozen, and then slowly heated in a vacuum chamber to remove the ice crystals formed by the freezing process. The final product retains 98%[

citation needed] of its nutrition and weighs much less than before drying. The ratio of weight before and after drying depends strongly on the particular food item but a typical freeze-dried weight is 20% of the original weight. Today, one of the benefits of this advancement in food preservation includes simple nutritious meals available to handicapped and otherwise homebound senior adults unable to take advantage of existing meal programs.

[17][25][26]