ScienceRocks

Democrat all the way!

- Thread starter

- Banned

- #261

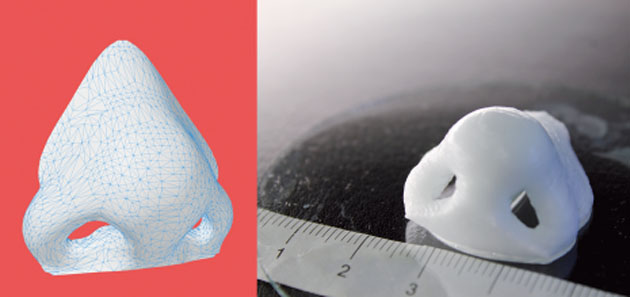

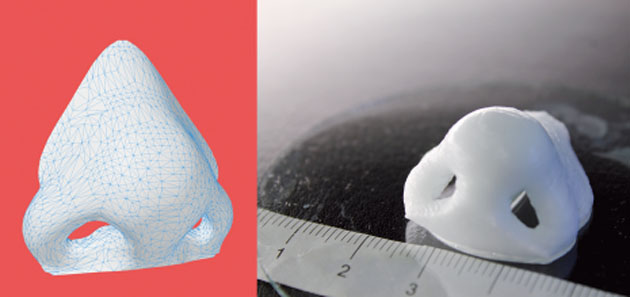

Researchers can now 3D-print nose cartilage in 16 minutes

by Mona Lalwani | @monalalwani | 6hrs ago

by Mona Lalwani | @monalalwani | 6hrs ago

Doctors have been employing 3D-printed tissue for years now. But even though the hype around 3D bioprinting has raised expectations that it will save lives and shorten donor wait lists, fully functional printed organs are not feasible yet. While we won't be seeing blood pumping printed hearts any time soon, getting a new nose could become easier.