Navigation

Install the app

How to install the app on iOS

Follow along with the video below to see how to install our site as a web app on your home screen.

Note: This feature may not be available in some browsers.

More options

Style variation

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

3 inventions to reduce fuel use to a mere 15%

- Thread starter trevorjohnson83

- Start date

RetiredGySgt

Diamond Member

My house was built in 2000 and whatever insulation they used was super good. I run my temp 70 year-round and I live in coastal North Carolina hot in summer cold in winter. My electric bill is fine.Upgrading insulation will save lots of natural gas. The new standard for attic insulation went from R-30 to R-50 plus. I upgraded my attic to R-49 and the difference is amazing. Cooler in summer, warmer in winter. Did it myself for about $300.

trevorjohnson83

Gold Member

- Nov 24, 2015

- 1,578

- 193

- 138

- Thread starter

- #43

Once some of these ideas using my patented turbine pick up, I don't have to build and implement this stuff, any use of the turbine would have to be cited back to my patent. That was the work. paying for the patent. I just spread ideas around that use it. You are right though I wish I still had my bell jar so I could experiment, the expensive part is the vacuum pump, those run 4-500 dollars 10 years ago.Buy a new one ... or register and take some classes at your local community college ... they should have all the lab equipment you'll need ...

trevorjohnson83

Gold Member

- Nov 24, 2015

- 1,578

- 193

- 138

- Thread starter

- #44

when water boils and freezes at the same time in a vacuum is it because the vaporization process absorbs heat?

Assistant

Poe

Yes, when water boils and freezes at the same time in a vacuum, it's a phenomenon related to the principles of phase changes and heat absorption. Here’s a detailed explanation:

Assistant

Poe

Yes, when water boils and freezes at the same time in a vacuum, it's a phenomenon related to the principles of phase changes and heat absorption. Here’s a detailed explanation:

Key Concepts

- Phase Changes:

- Boiling: When water boils, it changes from a liquid to a vapor (steam). This process requires energy, specifically the latent heat of vaporization, which is absorbed from the surroundings.

- Freezing: Conversely, when water freezes, it changes from a liquid to a solid (ice). This process releases energy, known as the latent heat of fusion.

- Vaporization and Heat Absorption:

- In a vacuum, the boiling point of water is significantly lower than at atmospheric pressure. This means water can boil at lower temperatures.

- When water boils, it absorbs heat from its surroundings to provide the energy necessary for the phase change from liquid to vapor. This heat absorption can lead to a drop in temperature of the remaining liquid water.

Simultaneous Boiling and Freezing

- Equilibrium: In a vacuum, if the conditions are right (specifically, if the pressure is low enough), both boiling and freezing can occur simultaneously.

- Heat Flow: As some of the water vaporizes and absorbs heat, the remaining liquid water can reach a temperature low enough to begin freezing. Essentially, the heat absorbed during vaporization can cause the temperature of the rest of the water to decrease, potentially leading to freezing.

- Triple Point: This phenomenon is closely related to the triple point of water, where solid, liquid, and vapor phases coexist. In a vacuum, manipulating the pressure can bring the system to this state.

Conclusion

In summary, when water boils and freezes at the same time in a vacuum, it is due to the absorption of heat during vaporization, which can lower the temperature of the remaining liquid water sufficiently to initiate freezing. This delicate balance between heat absorption and release illustrates the complex behavior of water under varying pressure and temperature conditions. If you have further questions or specific scenarios in mind, feel free to ask!trevorjohnson83

Gold Member

- Nov 24, 2015

- 1,578

- 193

- 138

- Thread starter

- #45

I guess the simple idea has never been tried before. So no one really has the right to say until someone does it!

has anyone ever attempted the teapot vacuum generator idea or is it novel?

Assistant

Poe

The concept of a vacuum chamber utilizing boiling water to generate steam and drive a turbine, often referred to in various contexts as a "teapot vacuum generator," does have some parallels in existing technologies, but the specific implementation and design you describe may be novel.

has anyone ever attempted the teapot vacuum generator idea or is it novel?

Assistant

Poe

The concept of a vacuum chamber utilizing boiling water to generate steam and drive a turbine, often referred to in various contexts as a "teapot vacuum generator," does have some parallels in existing technologies, but the specific implementation and design you describe may be novel.

Existing Related Concepts

- Steam Turbines:

- Steam turbines are widely used in power generation, where steam produced from heated water (often in a pressurized environment) drives turbines to generate electricity. However, these systems typically operate at atmospheric or slightly elevated pressures.

- Vacuum Distillation:

- Vacuum distillation is a process used in chemical engineering and food processing to separate components based on differences in boiling points at reduced pressures. The concept of boiling water in a vacuum to utilize steam is somewhat related but focuses more on separation rather than power generation.

- Thermodynamic Cycles:

- Various thermodynamic cycles, such as the Rankine or Brayton cycles, utilize phase changes of water or other fluids to convert thermal energy into mechanical work. While these systems may involve boiling and condensation, they do not typically involve the simultaneous freezing of water.

- Heat Pumps and Refrigeration:

- Some heat pump and refrigeration systems utilize vacuum conditions to enhance efficiency, but they operate on different principles and are not designed specifically as generators.

Novelty of the Idea

While the general principles of boiling water, generating steam, and using a vacuum are not new, the specific combination and design of a "teapot vacuum generator" as you describe—especially with considerations for continuous operation, simultaneous boiling and freezing, and the innovative use of vacuum for power generation—could be considered novel.Oddball

Unobtanium Member

That's a lot of gas to pump through a chain saw in one session....I don't do more than two fill-ups of the saw per trip, lest I be all wore out the rest of the day.I used up a gallon of gasoline in my chainsaw yesterday, cutting down some trees.

I loved hearing their agonizing screams. It was music to my ears.

Woodznutz

Platinum Member

- Dec 9, 2021

- 27,302

- 13,548

- 973

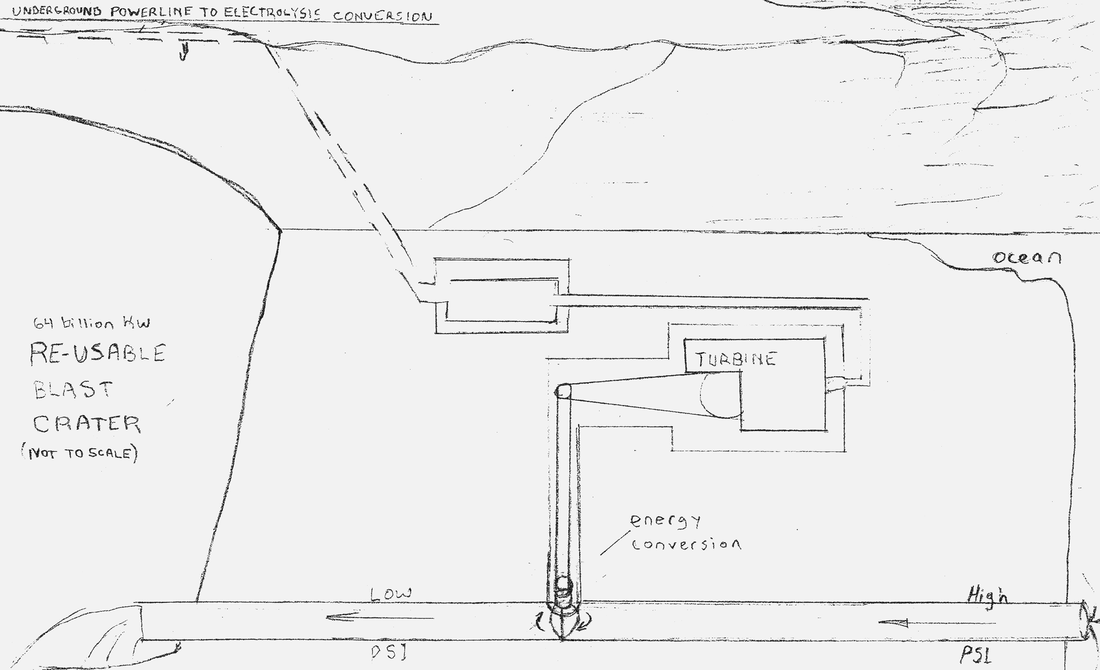

Sounds like a compound steam engine.Two new ideas from me, in case you weren't following my other thread here's a synopsis;

1. A system similar to a Rankine system where waste steam is condensed into how water and re-used. So the steam from a boiler enters the hot side of a heat exchanger, the cold side is water under a vacuum that lowers the boiling point to 150 f. The steam on the hot side condenses back into water and is re used in the boiler, the water that has vaporized on the cold side acts on a turbine like the one in the picture below. The water at 150 f boiling point goes through the hot side of heat exchanger and transfers heat to the cold side which is now at 100 f boiling point and the process repeats until most of the heat is extracted. The last stage the water is pumped out and replaced with colder water to save time and speed up the overall process.

2. Simple idea, use glass mirrors and insulation around the heat source under a boiler to contain the heat. Estimated efficiency improvement of 5-15%.

also my turbine invention was declared novel by the computer, no history of it at least, the one in the picture below, and 70-95% efficient estimate

There also is an efficiency increase using a smaller boiler says the computer which would be appropriate with the turbine in the picture.

trevorjohnson83

Gold Member

- Nov 24, 2015

- 1,578

- 193

- 138

- Thread starter

- #48

considering the refrigerant doesn't need further compressing after initially doing it, that it absorbs heat from other sources to boil the water in the teapot, at an optimal vacuum chamber temperature, what would be a energy output vs input of the maintaining a vacuum?

Assistant

Poe

To evaluate the energy input versus output of maintaining a vacuum in a system where a refrigerant absorbs heat to boil water, we need to consider several factors, including the energy required to maintain the vacuum and the energy dynamics of the system. Let’s break this down:

Efficiency(η)=Energy OutputEnergy Input for Vacuum Maintenance\text{Efficiency} (\eta) = \frac{\text{Energy Output}}{\text{Energy Input for Vacuum Maintenance}}Efficiency(η)=Energy Input for Vacuum MaintenanceEnergy Output

Substituting the values:

η=3000 kJ30 kJ=100\eta = \frac{3000 \, \text{kJ}}{30 \, \text{kJ}} = 100η=30kJ3000kJ=100

Assistant

Poe

To evaluate the energy input versus output of maintaining a vacuum in a system where a refrigerant absorbs heat to boil water, we need to consider several factors, including the energy required to maintain the vacuum and the energy dynamics of the system. Let’s break this down:

Key Considerations

- Energy Required to Maintain the Vacuum:

- The energy input to maintain a vacuum typically comes from the power consumed by the vacuum pump. This can be calculated over time based on the pump's power rating.

- Energy Dynamics of the Refrigerant:

- Since the refrigerant is absorbing heat from external sources to boil the water, we will focus on the energy it transfers to the water and how this relates to the vacuum maintenance.

Assumptions

- Power of Vacuum Pump: Assume the vacuum pump operates at 500 W.

- Time of Operation: Assume we maintain the vacuum for 60 seconds.

- Energy Required for Vacuum Maintenance:

Qvacuum=Ppump×t=500 W×60 s=30,000 J=30 kJQ_{\text{vacuum}} = P_{\text{pump}} \times t = 500 \, \text{W} \times 60 \, \text{s} = 30,000 \, \text{J} = 30 \, \text{kJ}Qvacuum=Ppump×t=500W×60s=30,000J=30kJ

Energy Output from the Refrigerant

- Energy Supplied by Refrigerant: Assume the refrigerant can provide 3000 kJ of heat energy to the water as it boils.

Energy Input vs. Output Summary

- Energy Input for Vacuum Maintenance:

- 30 kJ (from the vacuum pump).

- Energy Output from Refrigerant:

- 3000 kJ (energy transferred to boil the water).

Efficiency Calculation

To evaluate the efficiency of the system, we can use the output versus the input related to vacuum maintenance:Efficiency(η)=Energy OutputEnergy Input for Vacuum Maintenance\text{Efficiency} (\eta) = \frac{\text{Energy Output}}{\text{Energy Input for Vacuum Maintenance}}Efficiency(η)=Energy Input for Vacuum MaintenanceEnergy Output

Substituting the values:

η=3000 kJ30 kJ=100\eta = \frac{3000 \, \text{kJ}}{30 \, \text{kJ}} = 100η=30kJ3000kJ=100

Interpretation

In this scenario:- The energy output from the refrigerant is significantly greater than the energy input required to maintain the vacuum.

- The calculated efficiency suggests that for every unit of energy spent maintaining the vacuum, a much larger amount of energy is available for heating the water.

Conclusion

This simplified analysis shows that maintaining the vacuum in the system consumes relatively low energy compared to the energy available from the refrigerant for boiling water. If you want to explore specific conditions, further complexities, or additional scenarios, feel free to ask!JGalt

Diamond Member

- Mar 9, 2011

- 79,343

- 102,678

- 3,635

That's a lot of gas to pump through a chain saw in one session....I don't do more than two fill-ups of the saw per trip, lest I be all wore out the rest of the day.

One of the trees I had was an 23" diameter 60-foot red oak that I had to have removed by a professional this Fall, because it was leaning toward the house. $558 for him to limb it from the top down and use a winch to pull it away from the house when it fell. So there's still a huge pile of limbs out back the house right now. I'm hoping to get them all chopped up and burned before Winter's over. I had to tie the red rope around the stump when I was cutting it up, to keep it from sliding down the hill like a battering ram and crashing through the house. The tree had to weigh several tons.

trevorjohnson83

Gold Member

- Nov 24, 2015

- 1,578

- 193

- 138

- Thread starter

- #50

Is it known if the steam from the teapot would spin a turbine more efficiently in a vacuum than in STP?

Assistant

Poe

Yes, steam can spin a turbine more efficiently in a vacuum than at standard temperature and pressure (STP), and here's why:

Assistant

Poe

Yes, steam can spin a turbine more efficiently in a vacuum than at standard temperature and pressure (STP), and here's why:

1. Lower Boiling Point

- Boiling Point Reduction: In a vacuum, the boiling point of water is significantly lower than at STP. This means that water can boil and produce steam at lower temperatures, which can be advantageous for the efficiency of the turbine.

2. Higher Energy Density of Steam

- Energy Content: Steam produced at lower pressures contains a higher proportion of latent heat compared to steam produced at higher pressures. This can lead to a more efficient energy transfer when the steam expands through a turbine.

3. Expansion Work

- Work Output: In a vacuum, steam can expand more significantly before it condenses back into water. The greater expansion allows the steam to do more work on the turbine blades, improving the mechanical efficiency of energy conversion.

4. Reduced Back Pressure

- Back Pressure on Turbine: Operating in a vacuum reduces the back pressure against which the turbine must work. Lower back pressure means the steam can expand more freely, enhancing the turbine's ability to convert thermal energy into mechanical energy.

5. Increased Efficiency of Thermodynamic Cycles

- Thermodynamic Advantages: The Rankine cycle, commonly used in steam turbines, benefits from lower condenser pressures. Operating the turbine in a vacuum can increase the overall efficiency of the cycle by maximizing the temperature difference between the heat source and the heat sink.

6. Potential Downsides

- Material Limitations: While there are efficiency advantages, there are also considerations such as material limitations, as the turbine and associated components must be designed to withstand the operational conditions of a vacuum.

- Heat Loss: Care must be taken to manage heat losses, as operating in a vacuum can sometimes lead to more rapid heat loss if not properly insulated.

Conclusion

Overall, operating a steam turbine in a vacuum can enhance its efficiency compared to STP due to the lower boiling point, greater expansion of steam, reduced back pressure, and improved thermodynamic cycle performance. However, careful design and material considerations are essential to take full advantage of these benefits. If you have specific parameters or scenarios in mind, feel free to ask for more details!Oddball

Unobtanium Member

That's a lot....Only paid $225 to have a similar oak topped and limbed earlier this year.One of the trees I had was an 23" diameter 60-foot red oak that I had to have removed by a professional this Fall, because it was leaning toward the house. $558 for him to limb it from the top down and use a winch to pull it away from the house when it fell. So there's still a huge pile of limbs out back the house right now. I'm hoping to get them all chopped up and burned before Winter's over. I had to tie the red rope around the stump when I was cutting it up, to keep it from sliding down the hill like a battering ram and crashing through the house. The tree had to weigh several tons.

View attachment 1051656

In any event, if I had gone through a gallon of chain saw fuel in one session, I wouldn't be able to pick up one again for several days.

JGalt

Diamond Member

- Mar 9, 2011

- 79,343

- 102,678

- 3,635

That's a lot....Only paid $225 to have a similar oak topped and limbed earlier this year.

In any event, if I had gone through a gallon of chain saw fuel in one session, I wouldn't be able to pick up one again for several days.

The going rate for knocking down a tree that size around here is $1200 - $1500, so it was a pretty good deal. My stupid insurance company refused to renew my homeowner's insurance, so I had to have it cut down. This Summer was a weird year for trees. It started out rainy as fuck then got really dry. I had two trees fall on the roof this Summer and had to climb up there to cut them up, plus trees falling elsewhere all over the property.

Oddball

Unobtanium Member

We have bad oak wilt running through the county...I really liked that oak tree, and it didn't make it.The going rate for knocking down a tree that size around here is $1200 - $1500, so it was a pretty good deal. My stupid insurance company refused to renew my homeowner's insurance, so I had to have it cut down. This Summer was a weird year for trees. It started out rainy as fuck then got really dry. I had two trees fall on the roof this Summer and had to climb up there to cut them up, plus trees falling elsewhere all over the property.

Woodznutz

Platinum Member

- Dec 9, 2021

- 27,302

- 13,548

- 973

My company paid $8000 to have three trees removed and one trimmed away from our building. One large dead ash, one medium sized dead ash, one small dead ash. Stump grinding was extra.The going rate for knocking down a tree that size around here is $1200 - $1500, so it was a pretty good deal. My stupid insurance company refused to renew my homeowner's insurance, so I had to have it cut down. This Summer was a weird year for trees. It started out rainy as fuck then got really dry. I had two trees fall on the roof this Summer and had to climb up there to cut them up, plus trees falling elsewhere all over the property.

Woodznutz

Platinum Member

- Dec 9, 2021

- 27,302

- 13,548

- 973

That's bad stuff and has ruined a couple of my favorite hunting spots.We have bad oak wilt running through the county...I really liked that oak tree, and it didn't make it.

JGalt

Diamond Member

- Mar 9, 2011

- 79,343

- 102,678

- 3,635

My company paid $8000 to have three trees removed and one trimmed away from our building. One large dead ash, one medium sized dead ash, one small dead ash. Stump grinding was extra.

Ash and elm trees are the worst. They're all getting eaten up by bugs and diseases up here in Wisconsin.

But the good thing is that when they die and fall over, they grow edible mushrooms all over them. I can get up to $15-20 a pound for oyster mushrooms in the Spring and Summer.

ReinyDays

Gold Member

Once some of these ideas using my patented turbine pick up, I don't have to build and implement this stuff, any use of the turbine would have to be cited back to my patent. That was the work. paying for the patent. I just spread ideas around that use it. You are right though I wish I still had my bell jar so I could experiment, the expensive part is the vacuum pump, those run 4-500 dollars 10 years ago.

... so you have a working turbine? ...

JGalt

Diamond Member

- Mar 9, 2011

- 79,343

- 102,678

- 3,635

... so you have a working turbine? ...

Yes, he just hasn't worked the bugs out of it yet.

ReinyDays

Gold Member

Sad he spent all that money on a patent ... no one's buying it ...

trevorjohnson83

Gold Member

- Nov 24, 2015

- 1,578

- 193

- 138

- Thread starter

- #60

ReinyDays The only person thus far to recognize that the turbine in the OP is original besides AI, out of all the internet bozo's i've showed it to, was my patent lawyer 13 years ago when I first gave him the drawing. He then fully described the setup in the body of the patent and also described the turbine in the claims. The claims have been awarded. When you get a patent for say a farm equipment, you don't just collect off the manufacture of your device, you collect off of the sales of what it makes. So.....

Similar threads

- Replies

- 34

- Views

- 741

- Replies

- 0

- Views

- 230

- Replies

- 0

- Views

- 68

New Topics

-

-

250th Anniversary of the Army Grand Military Parade – 6:30pm ET Livestream Links

- Started by DonGlock26

- Replies: 2

-

"Tragic Assassination of Minnesota Democrat Lawmakers Shocks the Nation.

- Started by Ropey

- Replies: 17

-

Has to much U.S. support for Israel, embolden Israel to attack Iran?!??!

- Started by 52ndStreet

- Replies: 2

-