ScienceRocks

Democrat all the way!

- Thread starter

- Banned

- #281

3-Year-Old with Extremely Large Head Receives Groundbreaking Skull Replacement Surgery

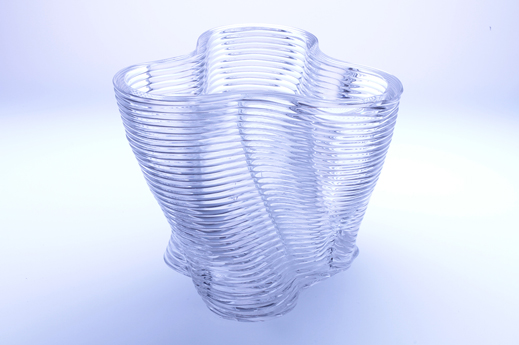

Surgeons and medical experts in China really seem to be on a roll lately when it comes to 3D printing medical implants. Over the past few weeks we’ve reported on several very impressive surgeries that have taken place thanks to 3D printed titanium implants. However, none of these come close to comparing to the latest surgery performed at the Second People’s Hospital of Hunan Province in China, on a 3-year-old little girl named Han Han. [...] Surgeons and medical personnel used 3D data that they acquired as well as CT scanners to create models for 3D printing three titanium mesh skull implants which would together replace Han Han’s entire top portion of her skull.

Surgeons and medical experts in China really seem to be on a roll lately when it comes to 3D printing medical implants. Over the past few weeks we’ve reported on several very impressive surgeries that have taken place thanks to 3D printed titanium implants. However, none of these come close to comparing to the latest surgery performed at the Second People’s Hospital of Hunan Province in China, on a 3-year-old little girl named Han Han. [...] Surgeons and medical personnel used 3D data that they acquired as well as CT scanners to create models for 3D printing three titanium mesh skull implants which would together replace Han Han’s entire top portion of her skull.